New products coming soon!

February 19, 2021

We're constantly developing our product portfolio, here's more...

We are pleased to announce that our laboratory in Harrogate will further add to its Torque capabilities. We will be bringing on line in the next few months High Torque capabilities, this will be used to perform calibrations on Torque Multipliers. Working in conjunction with one of our partners, COMAR ENGIEERING have designed and will be building the dedicated rig, and we will be relying on the NORBAR range of sensors and instrumentation to complete this process development.

So how do Torque Multipliers work?

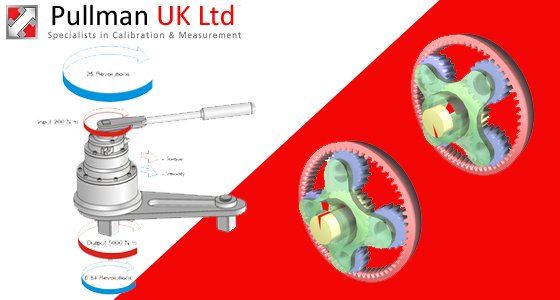

Torque multipliers typically employ an epicyclic gear train having one or more stages. Each stage of gearing multiplies the torque applied. In epicyclic gear systems, torque is applied to the input gear or ‘sun’ gear. A number of planet gears are arranged around and engaged with this sun gear, and therefore rotate. The outside casing of the multiplier is also engaged with the planet gear teeth, but is prevented from rotating by means of a reaction arm, causing the planet gears to orbit around the sun gear. The planet gears are held in a ‘planet carrier' which also holds the output drive shaft. As the planet gears orbit around the sun gear, the carrier and the output shaft rotate together. Without the reaction arm to prevent rotation of the outer casing, the output shaft cannot apply torque.

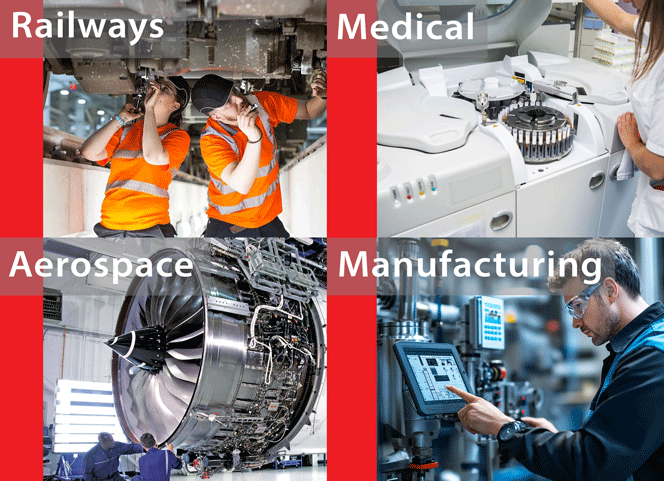

Where are Torque Multipliers commonly used?

Torque multipliers are most often used when a compressed air powered impact wrench is unavailable due to remote locations without power, or where cost considerations require manually operated tools which do not require any power supply or power source of any kind. There are many instances where screws, bolts and other fasteners are secured so tightly that using a typical lug wrench with a cheater bar is not sufficient to loosen them. These include automotive repair and assembly, Rail Infrastructure, construction projects, heavy equipment maintenance and other instances where high torque output is needed. A torque multiplier allows the user to generate high torque output without the use of an air compressor or impact gun.